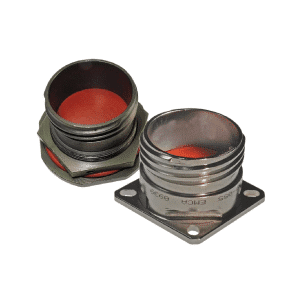

At EMCA, we supply a comprehensive range of high-performance dummy receptacles engineered to protect and safely stow unused connectors in aerospace, defence, transportation, and other high-reliability applications.

Our dummy receptacles maintain connector integrity by preventing physical damage, dust and fluid ingress, and other forms of contamination during transport, storage, maintenance, or standby conditions.

Designed for full compatibility with MIL-DTL-38999, VG96912, JN1003, and other international connector standards, EMCA dummy receptacles deliver rugged, reliable protection in the harshest environments.

Explore our product families:

B3 Series – precision-designed for MIL-DTL-38999 Series III connectors.

B5 Series – tailored to VG96912 and JN1003 connector systems.

Whether for long-term system resilience or short-term connector protection, EMCA dummy receptacles provide trusted performance and secure retention across global industries.

Together with our backshells and protective caps, EMCA dummy receptacles form part of a comprehensive connector accessory portfolio – delivering complete protection, cable management, and long-term reliability for demanding interconnect systems.

To suit Connector Series:

Connector Specification:

To suit Connector Series:

Connector Specification:

To suit Connector Series:

Connector Specification:

A dummy receptacle is a non-electrical insert that protects a connector’s interface when it’s not in use. It shields the shell and threads from dust, moisture, and damage, maintaining the environmental seal and alignment for future connections.

Pick a dummy that matches your connector series, size, and mounting style. Check these points:

Tip: If unsure, compare shell code and thread size, or contact EMCA for a quick match.

No. Dummy receptacles are mechanical only — they contain no contacts and do not carry current or signals. They’re for protection, not electrical use.

It usually improves performance by protecting critical surfaces. Problems only occur if the dummy is poorly fitted or not sealed properly, which can trap moisture or cause wear over time.

Yes, if the connector isn’t used electrically and the dummy meets all mechanical and environmental needs. Periodic inspection is still advised for long-term reliability.

Common references include MIL-DTL-38999, VG96912, VG95328, and JN1003 specifications. These define shell dimensions, threads, and sealing requirements. EMCA lists the compatible standard on each product page.