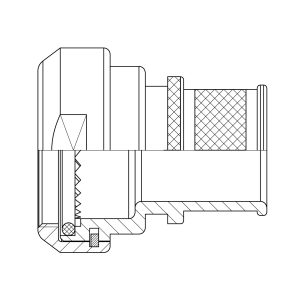

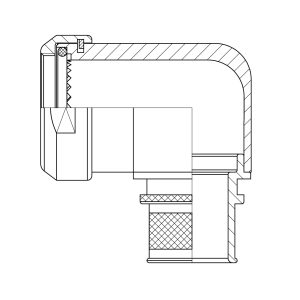

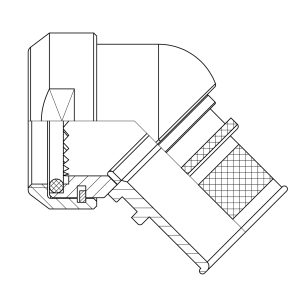

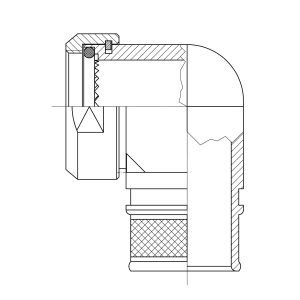

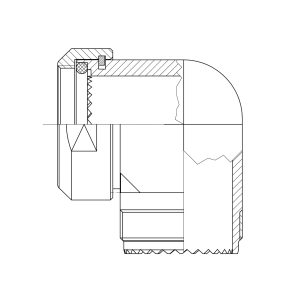

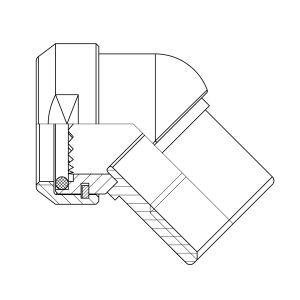

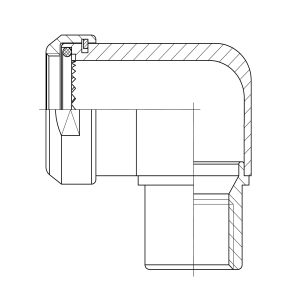

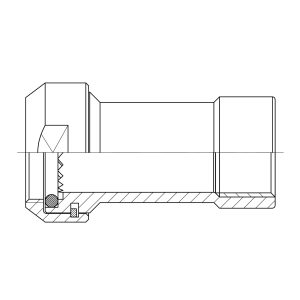

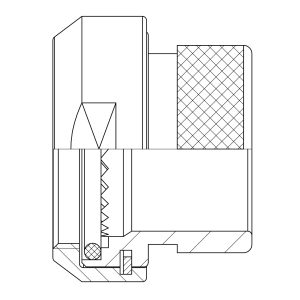

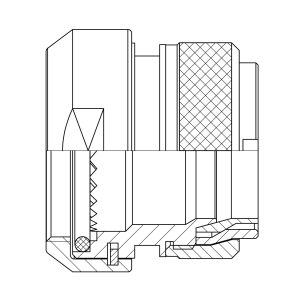

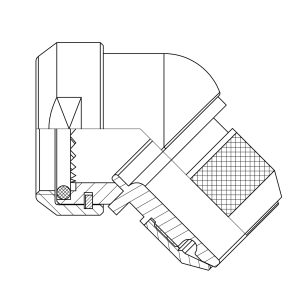

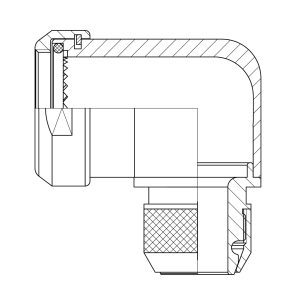

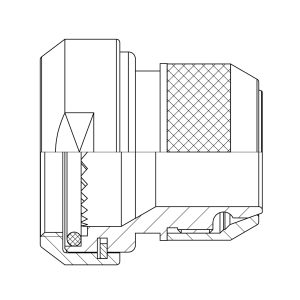

EMCA’s Series A3 backshells deliver high-performance EMC shielding and environmental protection for mission-critical connector assemblies. Available in straight, 45°, and 90° configurations, these backshells are engineered for secure cable management and space-efficient routing in demanding environments. Featuring band termination / constant force spring (CFS) platforms and robust strain relief options, Series A3 supports quick, reliable installations across a wide range of MIL-DTL-38999 (D38999) Series III and IV connectors. Trusted in aerospace, and high-reliability industrial systems, this series offers proven performance in harsh operating conditions.

Series A3 backshells are a direct replacement for:

| A37-524 A37-525 A37-526 |

4 | J | 08 | KN | ||

|---|---|---|---|---|---|---|

| Basic part number | ||||||

| Shell size code |

ARefer to table A for the required Shell Size code

|

|||||

| Material and plating code |

CRefer to table C for the required Shell Finish code

|

|||||

| Cable entry size |

BRefer to table B for the required Shell Entry Size code

|

|||||

| Option knurled coupling ring |

* Please refer to datasheets for all other backshell types.

All dimensions in mm (inch) unless specified otherwise.

| Shell Size | Shell Size Code |

|---|---|

| 08 (A) | 1 |

| 10 (B) | 2 |

| 12 (C) | 3 |

| 14 (D) | 4 |

| 16 (E) | 5 |

| 18 (F) | 6 |

| 20 (G) | 7 |

| 22 (H) | 8 |

| 24 (J) | 9 |

| Entry Size Code | ØD2 min. | ØD3 max. |

|---|---|---|

| 03 | 4.7 (0.185) | 13.9 (0.547) |

| 04 | 6.3 (0.248) | 13.9 (0.547) |

| 05 | 7.9 (0.311) | 15.5 (0.610) |

| 06 | 9.5 (0.374) | 17.2 (0.677) |

| 07 | 11.1 (0.437) | 18.7 (0.736) |

| 08 | 12.7 (0.500) | 20.3 (0.799) |

| 09 | 14.2 (0.559) | 21.9 (0.862) |

| 10 | 15.8 (0.622) | 23.5 (0.925) |

| 11 | 17.4 (0.685) | 25.1 (0.988) |

| 12 | 19.0 (0.748) | 26.7 (1.051) |

| 13 | 20.6 (0.8115) | 25.1 (0.988) | 14 | 22.2 (0.874) | 29.9 (1.177) |

| 15 | 23.8 (0.937) | 31.5 (1.240) |

| 16 | 25.4 (1.000) | 33.1 (1.303) |

| 17 | 27.0 (1.063) | 34.7 (1.366) |

| 18 | 28.6 (1.126) | 36.3 (1.429) |

| 19 | 30.2 (1.189) | 37.9 (1.492) |

| 20 | 31.8 (1.252) | 39.5 (1.555) |

| 21 | 33.3 (1.311) | 41.1 (1.618) |

| 22 | 35.0 (1.378) | 42.7 (1.681) |

| 23 | 36.5 (1.437) | 44.3 (1.744) |

| 24 | 38.1 (1.500) | 45.9 (1.807) |

| Material & Plating Code | Technical Design | ROHS / REACH Complaint | Electrically Conductive | Salt Spray Resistance (MIL Spec) | Salt Spray Resistance (VG Spec) |

|---|---|---|---|---|---|

| J | Black Hybrid finish

|

Yes | Yes | 500 hrs | 5 days cyclic |

| U | Olive drab Hybrid finish

|

Yes | Yes | 500 hrs | 5 days cyclic |

| 5 | Electroless nickel Base material: Al- alloy. |

Yes | Yes | 48 hrs | 48 hrs |

| 2 | Zinc-Nickel black

|

Yes | Yes | 500 hrs | n.a. |

| 6 | Cadmium olive drab

|

No | Yes | 500 hrs | 5 days cyclic |

| 9 | Marine Bronze Material: CuAl10Ni5Fe4 (CW307G). No additional plating. |

Yes | Yes | n.a. | n.a. |

| 1 | Stainless Steel / passivated |

Yes | Yes | n.a. | n.a. |

A D38999 backshell is a protective and functional accessory fitted to MIL-DTL-38999 circular connectors. It secures and supports the cable at the rear of the connector, preventing strain and vibration from damaging the contacts. In addition to strain relief, it helps maintain the connector’s environmental sealing and ensures continuous EMI and RFI shielding. This makes D38999 backshells essential in aerospace, defence, and other harsh-environment applications where reliability is critical.

No. Each backshell is designed to match a specific D38999 connector series and shell size. Series I, II, and III connectors all have different coupling threads and configurations, so the correct match is essential to achieve proper mechanical fit, grounding, and environmental sealing. Always check both the connector part number and the backshell specification before selection to ensure compatibility.

D38999 backshells are engineered to preserve the connector’s full shielding performance by maintaining conductive metal-to-metal contact. Most include 360° shield termination platforms such as band straps or constant force springs, which ensure electrical continuity between the cable braid and connector shell. This design minimizes interference and signal loss, especially in systems exposed to strong electromagnetic fields.

D38999 backshells are available in a range of cable exit configurations including straight, 45°, and 90° angles. Straight backshells are typically used when there is adequate clearance behind the connector, while angled options are ideal for installations where space is limited or cable routing needs to follow a specific path. The correct angle can improve strain relief and simplify harness layout.

Yes. EMCA manufactures a comprehensive range of accessories compatible with MIL-DTL-38999 backshells, including dummy receptacles, protective caps, and shield termination hardware. These accessories support reliable connector installation, help maintain environmental and EMC performance, and simplify maintenance and storage when connectors are unmated.